Producing Quality ammunition should be the concern of anyone who manufactures ammunition regardless if they do it for personal use or for commercial sale. While the consumer has the responsibility to use the ammunition in accordance with manufacturers guidelines, you as the manufacturer, have the responsibility to make sure it is safe, functional and reliable.

It is Safe?

No one should be loading ammunition for commercial or personal use that is not safe. It is human nature to think of the most extreme situation examples of ammunition failing. Undoubtedly we have all heard of cases with firearms have catastrophically failed because of a squib load, or a hot load. In these instances it is not uncommon for serious injury to occur to the shooter. Eyes and fingers have been lost when a firearm fails due to a high pressure event.

Commercial manufacturers spend an inordinate amount of time and money to ensure their ammunition is safe. They are specifically looking for the 1 in a million type events and ask themselves “What if” all the time.

“What if a customer leaves our ammunition on the dashboard, in Arizona, during mid summer and then decides to load their gun and fire it.”

“What if a customer is hunting in Alaska in mid winter and leaves his ammo in the tent overnite?”

“If the powder measure on our loading machine is only accurate to +/- .5gr? Will .5gr overcharge cause a high pressure event?”

“If the loading machine seats a bullet .010″ deeper than nominal would it still be safe to shoot?”

These questions, and more, are so regularly asked that SAAMI has guidelines for ammunition testing specifically for commercial manufacturers. I have not found these guidelines posted publicly.

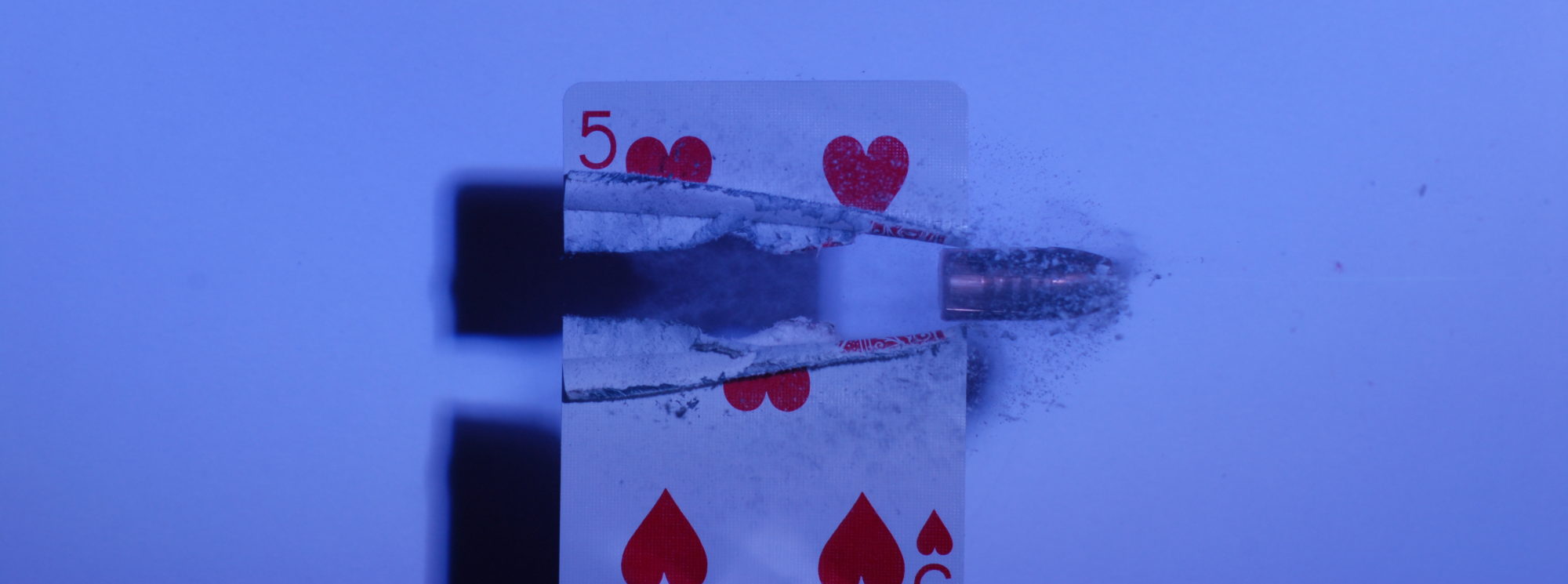

Because testing ammunition is destructive, meaning that that ammunition is consumed in the test and cannot be retested, any signs of trouble are headed. These may include, leaking primers, blown primers, cracks cases, high velocity/pressure, failure to fire, hangfires, low pressure/velocity, failure to cycle, and failure to feed.

Statistics are commonly employed to measure the performance of a small sample size and interpolate that to a larger lot size. If there is a statistical chance that an unsafe condition could exist, even if one isn’t directly observed, it is treated very seriously. Remember if a company produces 5-6 Million 5.56×45 rounds, and it thinks it has 1 in million odds of producing a single unsafe round, they can reasonably expect to have 5 to 6 potential liability suits per year.

Recalls cost at minimum $1 Million Dollars for a company such as Remington. Even if no injury has occurred. The marketing, loss in consumer confidence, and logistics, can ballon these costs well into the multimillion dollar range.

A firearm doesn’t have to fail catastrophically to be damaged by an unsafe round. Rounds that constantly leak around the primer pocket will erode the bolt face resulting in a permanently etched ring on the bolt face. A high pressure round can fatigue the metal, causing microscopic cracks, rendering the firearm unsafe to fire. This can be particularly dangerous as the firearm ends up catastrophically failing at some future date, potentially causing injury.

Is it Functional?

Functionality is defined differently depending on what the end goal of the round is. The obvious examples are “Does it feed in my firearm?” “Is it accurate?” “Does the bullet expand?”

Functionality is determined by the requirements of the consumer. As an individual loading for themselves this might be pretty simple, “It needs to feed, shoot, and extract in my firearm.” This seems to be overly simplistic, but when I am casting bullets to use as range fodder in my pistols, this is pretty much the extent of it.

A manufacturer may consider that ammunition is functional if that ammunition sells at a specific price point and customer is happy enough to come back and purchase more. They may advertise it’s functionality for hunting, self defense or target shooting. They spend a lot of money advertising and developing the function of the ammunition.

Functionality of a round goes beyond bullet selection. Different powders have different attributes that contribute to the functionality of the round and come at different price points. Different cases may be chosen for ammunition being sold as a premium brand verses ammunition that is budget. Primers play a key role in this as some primers add to the muzzle flash, and that might not be desirable for the function of your ammunition.

Is it Reliable?

This is arguably the most important characteristic that the consumer will judge your ammunition on. It is more common to come across ammunition that is unreliable then ammunition that is unsafe to fire. Both may have the same effect, namely, you won’t be in business anymore.

Reliability can be defined as consistency? Does it achieve its functionality on a regular basis? How regular? Ammunition that is billed as being a premium target round will not be considered very reliable if it consistently throws a flier every few shots.

Customers are usually not very happy if they have or two rounds in a box of 100 that refuse to fire. They may be more tolerant of ammunition that has malfunctions if it is on the shooting range and the ammo was cheap, but they are less forgiving when they are on a once in a lifetime guided hunt spending $100k or more only to have a $5.00 premium round fail to fire.

This is true if the bullets usually expand, rather then always expand. Like functionality, reliability might have different standards given the different requirements of the ammunition.

Some Examples

Self Defense Ammunition Testing

There was fairly recent bullet company that produced ammunition that had a radical design. Primarily marketed as a self defense round it looks wicked. They produced many different calibers, and sold it as a premium ammunition. The features of this ammunition was primarily the bullet, which would expand and fragment impressively in ballistic gelatin.

We obtained a sample of this ammunition and proceeded to test it. This is a regular thing among manufacturers as they are doing in house competitive comparison to their own products. On several occasions the bullet failed to exit the bore, when subjected to -20 Deg F for 24hrs.

This is ammunition that was on the market and was likely being carried in firearms at the time we tested it. In our opinion it was not safe. Additionally when fired through different types of barriers the bullet would not expand or fragment reliability. Failing standardized FBI protocol testing.

This ammunition is still on the market. It is possible that they issues we observed at the time were fixed. Which is why this will remain nameless.

The features of the ammunition were impressive, however it failed to be a safe and reliable option. If quality was judged only on the features, it would likely rank high, but being unable reliability deliver on the advertised features makes it ammunition that is of suspect quality. Additionally creating a potential dangerous situation of a bullet stuck in the bore is a liability.

Long Range Precision Limitations

When assessing the capability of a new long range precision round we wanted to determine its accuracy potential. This was ammunition that we commercially produced on loading equipment in house. This was not ammunition that with carefully measured charge weights loaded on single stage presses.

In assessing the ammunition we measured velocity, pressure, and group size in an underground control lab. The ammunition shot groups that were consistently .5 or better inches at 100 yards and would shoot nearly 1.2 to 1.4in groups at 300 yards. This was excellent target ammunition. So where did we find the limitation?

By measuring the velocity we could evaluate the Average, Min, Max, Extreme Spread and Standard Deviation of the ammunition. This was a measure of how consistent (reliable) the ammunition was. The velocity was found to be very consistent with a Standard Deviation averaging around 10fps. This means that 68% of the shots would be within +/-10 FPS of the Average. 95% of the shots would be within +/-20fps of the Average, and 99.7% of the shots would be within +/-30fps of the Average.

If someone wanted to know how precise the ammunition was all they would have to look at was the possibility of getting a velocity that was higher or lower than the Average and to see what those extremes would do to group size over distance. Any differences in velocity results in vertical stringing on the target.

If the average velocity of the rounds was 2,700 fps, and you wanted to know roughly the accuracy potential of the ammunition was, you would take 2690fps and 2710fps along with the rest of the load data and plug it into a Ballistic Calculator. At 200 yards the difference is so slight that you wouldn’t observe it. The extremes in bullet drop would be -3.92in to -4.01in. However at 1000 yards the bullet drop -368.86 to -375.33 has a 7in difference.

With that said only 68% of your rounds will be within 10fps of the mean. So you what about the rounds that fall outside of this? Well 95% of the rounds with be within +/-20 fps of the Average. This means at the extreme ends the velocity could be as low as 6820 or as high as 2720 FPS. Again at two hundred yards these differences would be so slight (Under 1/4in) we wouldn’t notice them. However if we extend out the range to 1,000 yards the group will open up to 12.9in. This is important as it exceeds 1 MOA (10.47in is 1 MOA at 1000 yards).

So how good is good enough?

We know that 68% time the bullet will likely fall in a 7in circle at 1000 yards, but it is likely that 3 shots in 10 will fall outside of that circle but land within a 12.9in circle. Furthermore one in twenty shots is likely to land outside of that 12.9 in circle.

Remember we are only looking at the velocity variation, we haven’t looked at about a dozen other variables that will determine where that shot lands at 1000 yards. All we can say is that under the best possible conditions, 95% of the time a bullet will land within a 12.9in circle.

For those demanding better potential, this load may not be for them, but the majority of people shooting, even precision shooters, this ammunition far exceeds their ability to shoot.

Wrap Up

Hopefully this provides some insight on how to look at ammunition quality. The last example we used some basic statistics. I specifically included that example as much of determining what meets quality is based in statistics, since it is impractical to measure every attribute of every round produced. This write up is an introduction on how to think about quality. In future write ups we will discuss using tools such as Excel to measure quality and control quality using Statistical Process Controls (SPC).