We all have to start somewhere when it comes to learning about a new hobby or interest. It was not long ago that purchasing a book was the first thing people did, yes, even when the internet existed. When I was getting into handloading and reloading, I bought several books on the topic, The ABC’s of Reloading being only one of many. I read and studied it’s pages several times before getting up the confidence to assemble my first few loads.

Once I had the confidence to try those first few loads this book went on the bookshelf. If I had questions most of the loading manuals have a “How to” section that addresses how to set up a crimp die, or covers the basics of measuring distance of lands. That is likely the great flaw in this book, there is no load data offered, so unless you curious about what a balloon head cartridge looks like, you may never reference it again.

Then again Chapter 4 on Powders includes individual write up on some of the powders available at the time the book was published. Given some of these powders are now obsolete (hopefully this was updated in the 9th Edition) it acts as a means of reference for when we do find that odd canister of powder at an estate sale or in the back of your powder cabinet. Conversely it may be a reason to pick up previous editions, sometimes its just good to have short write ups on powders and what they were used for.

In terms of giving a definitive guide on all things related to reloading, from the safety aspects, to setting up dies, to powder selection, casting, loading black powder cartridges and a design for a NRMA reloading bench, this book is excellent. It goes far beyond a basic how to guide, as it has many articles that discuss things like Non-Toxic Shot, and Match Loading for Black Powder Cartridges. Some of these topics you do not realize you’re curious about until it is brought up.

There is some dated information, an I do not mean dated as in, I have the 8th Edition and there’s the 9th Edition. Just information that is no quite true anymore, it may have been when first written but made obsolete by manufacturing and technology advances. An example of this is in chapter 4 when the author is discussing pressure.

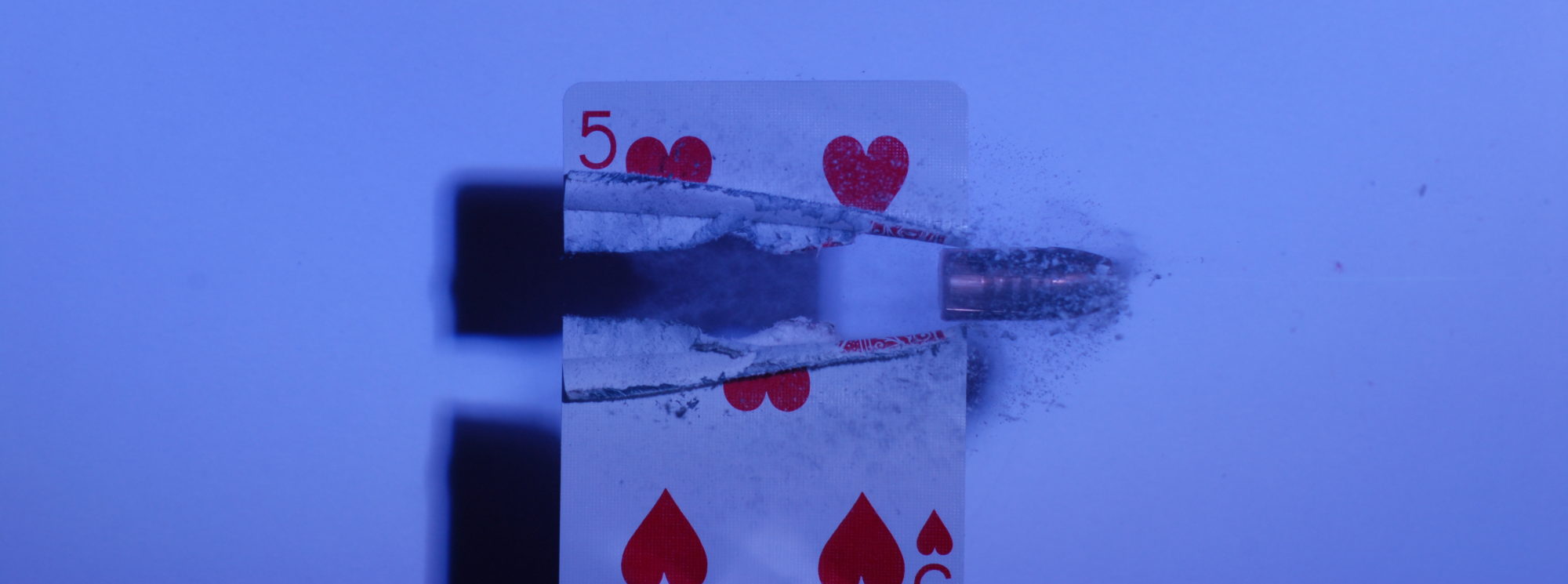

It is stated that brass cases are not safe at pressure exceeding 60,000psi. This may have been true at the time, but we now have close to 50 or so cartridges with SAAMI Maximum Average Pressures of +60,000psi. When SAAMI sets these service pressures, there are corresponding proof pressures, and manufacturers need to produced ammunition loaded to these proof pressures for use in proofing firearms. Very often proof loads use the same brass case, loaded hotter, but have to be safe. I.E you cannot have case head separations or blown primers. Average proof loads can be over 70,000psi.

Some of the terminology may be a bit different then what some people are used to, for example the hole between the primer pocket and the powder chamber is referred to as a vent hole. I guess I have never heard it referred to as that, we always call it a flash hole. The author takes a bit more conservative approach to safety then I am comfortable with by stating there is only one way to do it safety. I want people to be safe, and as he points out, it only takes one incident to at the very least ruin a firearm. I also want people to understand what they are doing well enough to develop a process that works for them. It is a difference of opinion.

Another difference of opinion, is the insinuation that all compressed loads will result in high pressures, which is not something I’ve observed at all. In fact usually it is quite the opposite, if I need to compress the load, it means I’m using a powder that is likely too slow burning, and I’m not going to get the pressures (thus performance) I want. Manufacturers shy from compressed loads as they create QA/QC issues with maintaining a consistent COAL. The powder pushes the bullet out (compress loads do not like being compress and the powder column acts as a spring).

Pressure per grain tend to be pretty linear when you are talking about differences of +/- 1.0gr which is often the difference between 98% to 110% load densities. Pressures do not suddenly spike when you hit 101% load density. The cavate may be this, if you are seating the bullet deeper on a charge, reducing available volume, and potentially increasing neck tension, then you will most certainly increase pressure.

This is turning into a bit of a negative review, it is not meant to be, only to point out that while this book is most definitely an excellent resource, there is some information that is not 100% agreed on by everyone. Which is why it is good to reference a few different sources before coming to a conclusion.

This is a book that every perspective reloader and should read prior to getting into the hobby so they know a bit what they are getting into. Even if you have no interest in reloading, but would like to learn more about the history of arms and ammunition’s, this book provides a good introduction to the history and progress made in ammunition development. The processes describe in this book are the same used in commercial ammunition manufacturing, it is just done on a larger scale.