It’s been almost a year since we embarked on this project. Much of the delays have been due to the expense of some of these components. The catalyst for making this all happen was the decision to launch a business conducting aerial surveys. I specialize in large area surveys of well over 100 acres. Which means that multirotor designs are out. The battery technology just isn’t there yet. Fixed wing is the only way to do. The problem is there is not such thing as a cheap fix wing drone. I’ve done some searching, and the cheapest you can get into it for is about $8k.

So we are continuing this build. The big advantage of this build is that we are building this of all of the shelf components including the fuselage. All of the programming is open source, the most expensive component of this build is the camera. The maintenance costs are going to be quit low and I can truly perform all the maintenance myself.

We left off with the airframe. It was complete for the most part, we had not added the Great Stuff foam to the wings, and at this time I’m not planning to do it quite yet. I’d like to see how things fly before I start adding more and more weight to the air frame.

By laying things out in Solid Works first it helps me develop as plan. When things start to come together, and I start routing wires, I usually make adjustments and I have to make adjustments to the CAD model. I’ll show the updated CAD model at the end of the post.

What Did We End Up Buying?

To embark on this journey I had to order about $1300 dollars worth of parts. When I’m finished with the build, I’ll probably list everything I ended up ordering and the mistakes that I made.

We decided to go with a slightly different transmitter then what we’d indicated we’d order. We went with the Taranis 9XD Plus SE 2019, this is an open source transmitter that allows use to get telemetry on the screen and if something breaks I can replace individual components. A very popular transmitter, but it did add a bit to the overall cost of the project at $300. The battery is sold separately at $20. Total cost on Amazon is about ~$320 plus tax. It comes with a case, which is nice.

We paired this transmitter with a X8R receiver. This is a very popular open source receiver that will connect to the Pixhawk. Commands given to the receiver are forwarded to the Pixhawk autopilot. The cost of the receiver is around $37 dollars. However in order to connect it to the Pixhawk you need a $10 cable. This makes the whole assembly about $50 after tax.

The Pixhawk Cube comes in kits that have the Here2 GPS and the RDF 900x wireless modem. The kits cost about $600 after tax. From what I can tell these kits are the most cost effective way to purchase these components. When ever I’ve seen professional units, such as the AeroMoa Talon, they use these components. There are other options for wireless modems and GPS units that are cheaper but I decided to follow the example of the professional systems on the market. Perhaps one day I’ll trial some of these cheaper components.

For the batteries we are going with what Flite Test recommended for this build, but we are doubling up on them. Hooking the batteries in parallel. The voltage will remain the same but the capacity will be effectively doubled. These batteries are fairly inexpensive at $20 a pop we ordered 6 of them total.

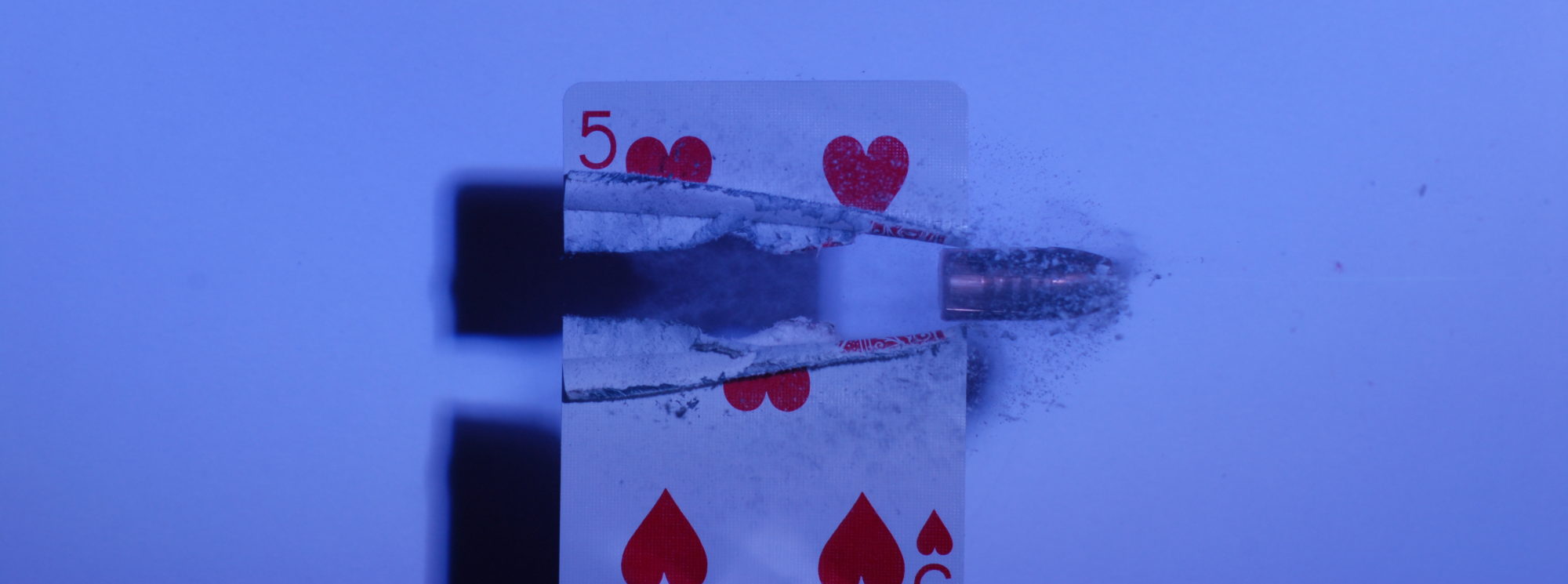

We ordered 1mmx300mm control rods. These turned out to be a mistake. The wire was too thin and the hinge on the control surfaces too stiff. So we ordered 4mm carbon fiber rod and made our own control rods.

I do like the adjustable pushrod connector, which we ordered a pack of about two dozen. These make it easy to install pushrods and then make adjustments to the length of the pushrod. The control horns are some I had on hand from a previous project, but I am thinking about swapping them out for the ones made by Flite Test. They are made from laser cut plywood. I just want to compare them and see if they are taller or if they offer much if any benefit over what I have on hand.

We also ordered a Air Speed Sensor Kit, which consists of an Pitot Tube, and a pressure differential sensor. This kit was about $50 but it didn’t have the right connector on the end to plug into the I2C port on the Pixhawk Cube. The connector was for the original Pixhawk. I had to break out my soldering iron and swap connectors out. I mounted the Pitot tube on the front middle of the drone. It is far enough back that I can put the drone on it’s nose and it has about an inch of clearance. I did this to try and ward off any damage that might occur if we had a crash.

Lastly, wires, lots and lots of wires. Everything needs to be connected together, and I am learning this project offers a lesson in wire management. We have two main wires that connected the batteries in parallels, then we have a chip that produces 5v power supply for the Autopilot. The power then goes to the ESC. Then we have wires that connect the Pixhawk to the wireless modem, RC Receiver, Airspeed Sensor, GPS Units, and servos. It is a mess of wires. I ordered a spare set of Pixhawk wires, and I ended up ordering a kit to make my own connections for the Pixhawk which are GH1.25 connectors and servo connectors.

There are other things I’ve had to order, such as spare props. I ordered some of the 3M Dual Lock Fastener strips. The best way to describe this stuff is 21st century Velcro. Its nice as it doesn’t have a hook or loop side. It locks together with a bunch of mushroom looking pins. They clasp together just as tight as velcro, and they do not retain debris like Velcro often does.

The Best Laid Plans…

We have had our fair share of troubles. Some we have previously touched on, for example the control rods were too flimsy. However we had issues with the original Taranis radio we ordered, after updating the firmware the radio refused to work. We returned it. So far I’m struggling to get the X8R receiver to bind with the Taranis radio. I do not know it is something I’m missing or if there is something wrong with the equipment, I’ve reach out to the company for some help.

These problems are more or less normal issues. This is just the nature of putting things together for the first time. As we handle the parts and we see how they fit in the air frame we get ideas. Sometime it is small adjustments such as the servo holes needed a bit of trimming but the servo’s fit in. (I was afraid the wires were going to be a pain to fish through but it was simple. The precut holes and the curved hemostats worked perfectly. ) Other time we have to remove a lot of material to get the autopilot to fit in with a comfortable amount of clearance.

The ESC was always going to be mounted on the what Flite Test refers to as a motor pod. There idea is that this pod can be swapped from model to model. I more or less permanently attached the pod, and used the 3M Dual Lock tape to stick in the ESC. (I want to say Velcro in…but it’s technically not Velcro). The ESC gets hot during use, so having good airflow over it helps to keep the temp within reason.

When fitting in the Pixhawk, I had to cut the hole in the fuselage a bit larger. Then I extended the notch on the cover to make clearance for the Cube to stick out of the top. After some contemplating I decided to plate the Here2 and my spare GPS on the cover of the fuselage.

As you can see in the above photo, the control rods were thin and flimsy. Definitely not what I wanted. This prompted me to build out the stiffer control rods out of 4mm carbon fiber rod replacing the flimsy 1mm music wire rods.

When contemplating where to mount the wireless modem I had a thought. I cut a hole in the rear of the fuselage and slipped it in the back. The two antenna stick out of the back of the drone and are fairly well protected. There was a bit of a clearance issue with the prop, which we solved by placing the motor on some brass standoffs. The modem is protected by a carbon fiber shell and is zipped tied in place.

Placing the motor on standoffs will shift the center of gravity rearward and will provide plenty of clearance to pull air into the core of the motor, hopefully providing better cooling. At this time the only downside I can see is if we have a hard landing on the rear, it could break the firewall from the model. Thought I have to admit hot glue offers a pretty decent bond to here.

The batteries mounted up in the fuselage center like I had modeled with out much of an issue. You can begin to see the mess of wires I need to manage in the photo below. We may need to add in some zip ties, shorten up some cables, and who knows what else.

Missing Something?

So if you are a keen observer, we are missing a key component. A camera. This is the last bit that we will need add to the build before we can start taking photos (Duh!). Well I’m waiting to add that for two reasons, the first being is expense. Camera’s are expensive, and can be ruined by a crash or a bad landing. The second, space is tight, perhaps a little two tight. Yes we can fit the camera in there, but I’ve already decided this will not be my final build.

We will do all of our initial mission planning, and flight testing with this airframe, but it is a sacrificial airframe. I am bound to make mistakes. It will crash and I’ll need to fix things figure out what went wrong and go from there. If it turns out this airframe is not going to be enough, they do make a larger airframe. I have a larger motor, ESC, and servo’s to move to larger airframe if required. However I think we are going to be ok.

There are some changes I’d like to make, one thing is to widen the airframe to accommodate the later 10×4.7 pitch prop. I believe this can be done pretty easily and make more efficient use of the motor. This will also give me a bit more space for the camera. I’d also like to expand the depth of the bay a little to give a bit more depth to accommodate the camera and lens.

To that end I’ve order two airframe kits from Flite Test. I’ll start with their base design and add the changes in when I build out the airframe. For now, the as build model is pictured below.