Let me first say, I’ve done a lot of rethinking about how I want this printer to be built. Which has lead to hours of design, redesign and studying what others have done. I feel the design is better, and I’ve been able to work through many of the challenges that we left unsolved in the original design that I had left off with in 2016.

As you can see there is plenty of work left to be done, but I feel I am at the point where I can start some of the fabrication. I received the 1in linear rod this week and decided to go ahead and get that ready to go.

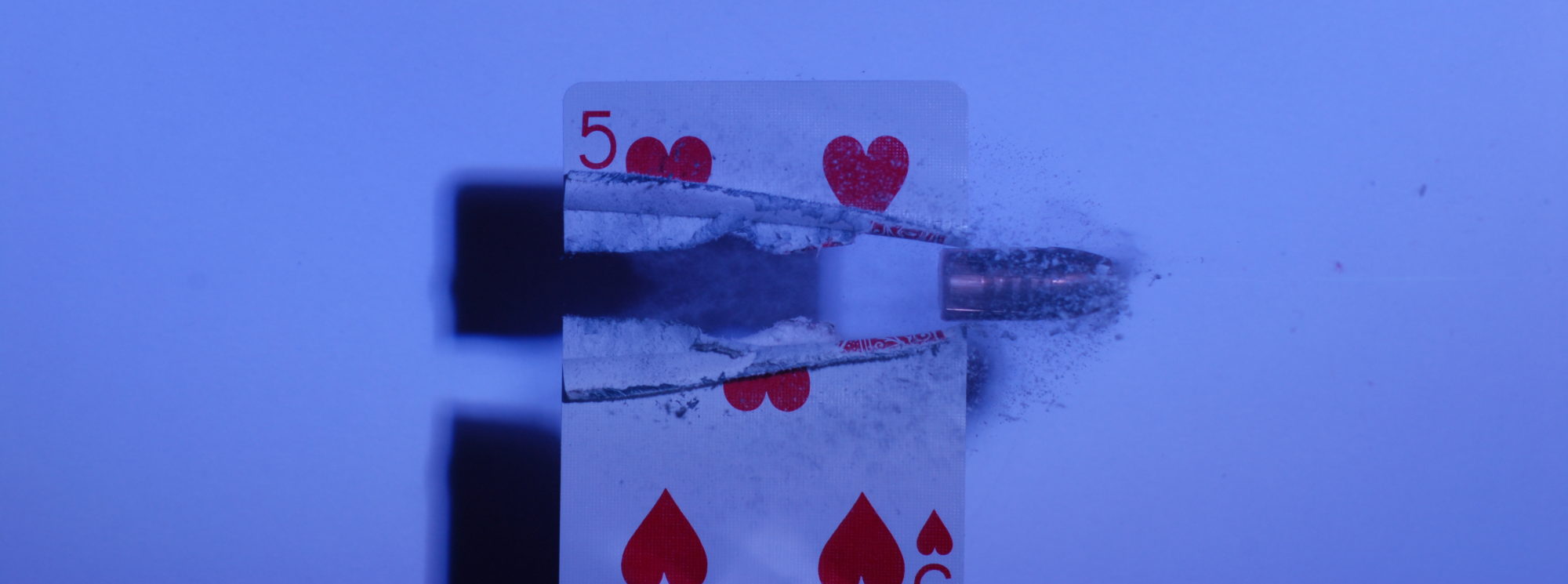

The linear rod is case hardened to .080in and I wasn’t certain on how it was going to machine or take threads. It made for an interesting experience. The Y-Axis rails are both 24in long with a 3/8-16 threaded hole on either side.

I cut the rods slightly over 24in so I could trim them down to equal lengths in the lathe.

When facing the material you could definitely see and feel where the case hardening was and where it ended. The insert tooling is all carbide, and it cut the hardened material despite not wanting to. Once you were through the hardened material the tooling tended to dish out the softer steel behind it. It tool a few passes of light cuts to try and get a good square end.

The spot drill and drilling the 5/16 hole for the 3/8-16 was pretty much like drilling any other steel. To me, when a drill is cutting into steel, it feels like I am pressing the tool into clay or putty. It has the most interesting feel to it, and you can feel when things change, like when the drill bit is loading up with chips.

This was the first time I’ve tapped a hole on the lathe using the tail stock. For the record, this not how you do it…

The tapping went well, it cut like any other steel I’ve tapped before.

In order to get the 2 Y-Axis rods made I had to repeat the face, drill, and tapping operations 4 times. When it was all done, I held both rods up and faced one until they were equal in length. I didn’t have to remove much material, just enough so they were as close to 24in as my tools would measure.