Most revolver owners know to check timing, lockup, end-shake, and barrel condition. But there’s one critical dimension that often flies completely under the radar — the cylinder throat. Many shooters never measure it, never think about it, and in some cases, don’t even know what it is. Yet this tiny section of each chamber can have a dramatic impact on accuracy, leading, and overall revolver performance, especially with cast bullets.

Several brands occasionally turn out revolvers with throats that are tighter than ideal — Ruger models are well-known for it, but Smith Wesson and others can show it too. And because the difference is often only a couple of thousandths of an inch, it’s easy to miss unless you go looking for it.

The throat is the last part of the chamber the bullet touches before it enters the forcing cone and barrel. If it’s undersized, the bullet gets squeezed down right before it’s supposed to engage the rifling. For cast-bullet shooters especially, that squeeze can lead to poor accuracy, erratic grouping, and heavy leading. Understanding how this works — and what to do if your revolver has the issue —can make a night-and-day difference in how a gun shoots.

Let’s break down why it happens, how to diagnose it, and what real-world fixes look like — including an example from the Smith & Wesson 329PD project that shows the whole process from start to finish.

Why Throat Size Matters

Imagine the bullet’s path: out of the case, across the cylinder gap, through the throat, into the forcing cone, and down the rifling. If the throat is smaller than the barrel’s groove diameter, the bullet gets squeezed as it exits the chamber. Once that happens:

- It may not fully re-expand.

- It can enter the rifling off-center and be damaged.

- Gas can blow by damage the bullet and disrupt stability.

- Soft cast bullets will lead the throat and forcing cone.

Cast bullets are the most susceptible, but even jacketed bullets suffer from mismatched geometry. Most experienced revolver shooters follow a simple guideline:

Throats should be the same as, or .001in–.002in; larger than, the barrel’s groove diameter.

Checking Your Own Revolver

You don’t need a high-end shop to spot trouble. Most shooters rely on:

- The Bullet Push Test: A properly sized bullet should pass with gentle pressure.

- Slugging the Barrel: Measure the groove diameter and compare it to the throat.

- Pilots or Plug Gauges: These provide a quick, reliable go/no-go check.

If bullets feel like they’re being forced through a tight choke point, you’ve found a problem.

A Real Example: Tuning a Smith & Wesson 329PD

To show how all this plays out in the real world, let’s look at work done on a Smith & Wesson 329PD, a lightweight .44 Magnum that’s famous for both its strengths and its quirks.

The Factory Return & Cylinder Upgrade

As part of ongoing testing, the 329PD went back to Smith & Wesson for an inspection and to have a new-old-stock (NOS) stainless, unfluted N-frame cylinder installed. S&W handled the job for a very reasonable fee, and the result was sharp-looking, albeit slightly heavier (but barely noticeable) pistol. Most importantly, it cured the famous sticky extraction issue the scandium guns can experience with magnum loads.

When the revolver came back:

- The cylinder gap was right in spec.

- The lockup was tight.

- The timing was spot-on.

Everything looked perfect … except the throat diameters.

Measuring the Throats

Each of the six chambers averaged .429in — not a disaster for jacketed bullets, but far from ideal. For cast bullets, it’s a recipe for trouble, especially when you consider:

Cast bullet diameter: .431in (May range from .430 to .434 depending on bullet mfg)

Cylinder throats: .429in

Barrel groove diameter: ~.430in

So, a .431in cast bullet would be squeezed to .429in, then immediately asked to re- expand to .430in as it hit the rifling. That’s a surefire way to get mediocre accuracy, gas blow-by, and heavy leading. Something had to be done.

Renting the Right Tools (A Great Option for DIY’ers)

Instead of buying a reamer outright, the fix started with 4D Reamer Rentals, a service a lot of shooters swear by.

They supply:

- Piloted, caliber-specific reamers

- All the right-sized pilots

- A generous rental window

- A tool that shows up sharp, clean, and ready to work

For a job you may only do once or twice in your life, renting makes perfect sense.

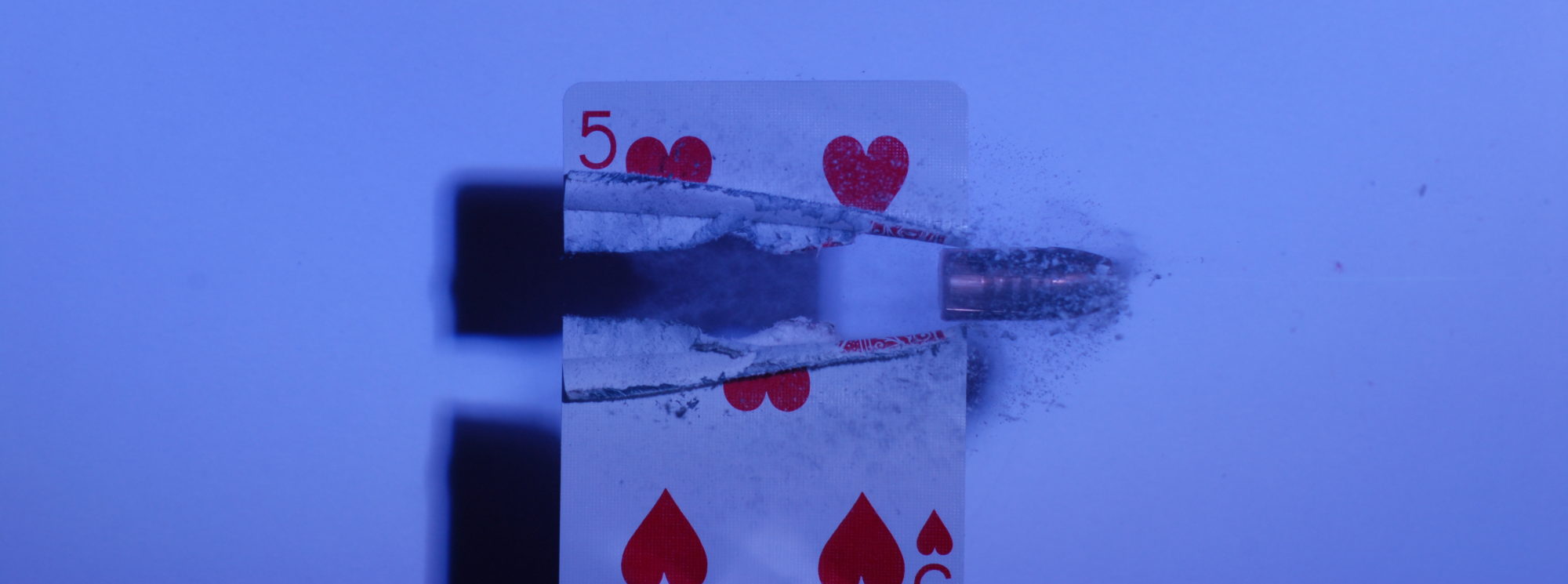

The Cutting Process

The reaming procedure itself is surprisingly straightforward:

- Remove the crane and cylinder assembly.

- Clamp the cylinder securely in a padded vise.

- Select the correct pilot for the reamer.

- Coat the tool with cutting fluid, or lightweight gun oil

- Turn the reamer by hand through each throat, slow, steady, no power tools.

- Clean chips often and check your progress.

Plenty of short instructional videos are available from 4D and others, so you’re not flying blind.

The Results

After reaming, every throat measured a perfect, uniform .431” exactly what the gun needed for cast-bullet accuracy.

But why stop there?

Finishing Touch: Flex-Hone Polishing

While you’re already in “garage gunsmith” mode, polishing the freshly cut throats is an easy improvement. Enter the Flex-Hone for Firearms — a simple but incredibly useful tool available in various diameters. Brownell’s sell their own brand but it is the same product.

Used correctly, Flex-Hones:

- Smooth the tool marks left by reaming

- Improve chamber finish

- Promote cleaner extraction

- Reduce leading

- Provide that slick, glassy interior feel

They come with clear directions, and manufacturers provide solid video guides on correct RPMs and motion. A quick polish with the appropriate hone left the S&W’s cylinder shiny and uniform, and the improvement was immediately noticeable.

The Payoff

Once the throats were properly sized and polished, the 329PD finally began to handle cast bullets properly. When a bullet can enter the forcing cone at the correct diameter — not squeezed down, not deformed, not gas-cut — everything falls into place: accuracy tightens, groups become predictable, and that stubborn, frustrating leading all but disappears.

For cast-bullet shooters, this isn’t just a minor tuning step; it’s foundational. Cast bullets rely on proper fit more than anything else. Hardness, lube, alloy, powder choice — all of it takes a back seat to that single requirement: the bullet must enter the barrel at the correct size. If the cylinder throats are too tight, no amount of load development or alloy tweaking will overcome the constant resizing and gas blow-by happening before the bullet even reaches the rifling.

Fix the throats, and suddenly every cast load you’ve worked on has a fair chance to shine. Velocity spreads shrink, bullets track straight, recoil feels more uniform, and even “problem children” loads often become useful and accurate. For a revolver that’s been stubborn or inconsistent with cast bullets, this single procedure can completely transform its behavior.

And the best part? The same formula applies across the board — whether it’s a Ruger known for snug throats, a Smith & Wesson that came out a little tight, or any other brand that’s wandered out of spec. The key principles remain simple and universal:

- Match throat diameter to the barrel’s groove diameter, ideally .001in–.002in, over.

- Use a piloted reamer for safe, consistent, perfectly aligned cuts.

- Polish the throats if you want the smoothest chambering and the least leading.

- Measure carefully, and if anything feels uncertain, consult a qualified gunsmith.

For many revolver shooters — especially those who favor cast bullets — correcting cylinder throat dimensions is often the single most impactful improvement they’ll ever make. It unlocks accuracy the gun always had the potential for but couldn’t deliver until the bullet was allowed to enter the barrel exactly as intended.

If you enjoy our content and want to support the site, visit our affiliate links and affiliate page. Purchases made through our partners may earn us a small commission at no extra cost to you.